The aviation industry is actively exploring and adopting Sustainable Aviation Fuels (SAFs) to reduce its environmental impact. The use of SAFs, with an emphasis on e-SAF, requires rigorous approval processes to ensure safety and compatibility with existing aviation infrastructure. This process is governed by standards such as ASTM D4054, which outlines the evaluation and certification of new aviation fuels.

Cost considerations: Currently, e-SAF production costs are substantial, estimated at around €4240 per tonne. Looking ahead, costs are projected to decrease to €1090-€2620 per tonne by 2050, subject to market growth and economies of scale. Nevertheless, a significant gap persists between e-SAF production costs and those of conventional kerosene, priced at €650 per tonne in June 2024. Market dynamics could further escalate e-SAF prices beyond current projections, impacting adoption by potential buyers and investment decisions by producers.

Policy considerarions: Policy interventions are crucial to overcoming these challenges and stimulating e-SAF supply. Governments worldwide are introducing measures like mandatory blending quotas and CO2 reduction targets for airlines, particularly in regions like the European Union and Germany. These policies aim to create a conducive environment for e-SAF adoption despite uncertainties in production volumes matching policy demands.

In terms of sustainability: Beyond carbon reduction, e-SAF’s role in sustainable development encompasses economic benefits like local value creation and social impacts such as community inclusion and human rights considerations. A holistic approach is crucial, integrating environmental, economic, social, and governance aspects to ensure e-SAF production contributes to a just energy transition.

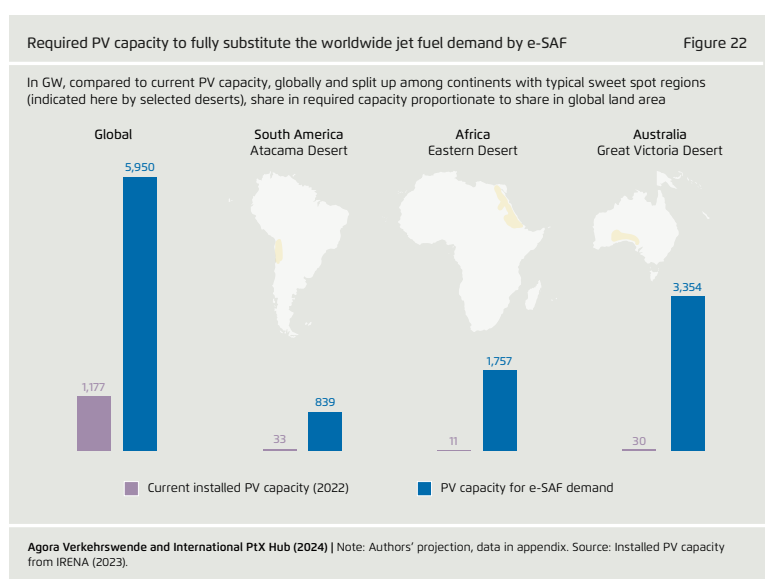

As showcased on Figure 22, the additional photovoltaic (PV) capacity needed for e-SAF production greatly exceeds current capacities, requiring a global effort to meet the approximately 5.9 terawatts needed. Although global PV capacity has grown significantly and will likely continue to do so, achieving the goal of defossilising aviation through e-SAF alone appears highly challenging and unlikely within the next few decades. To address this, all feasible and scalable options must be pursued. Currently, bio-SAF produced from waste oils and fats using the HEFA process seems the most economically viable, and it can be complemented by bio-alcohols from AtJ processes. However, given the limited availability of sustainable biogenic resources, increasing e-SAF production in parallel is crucial.

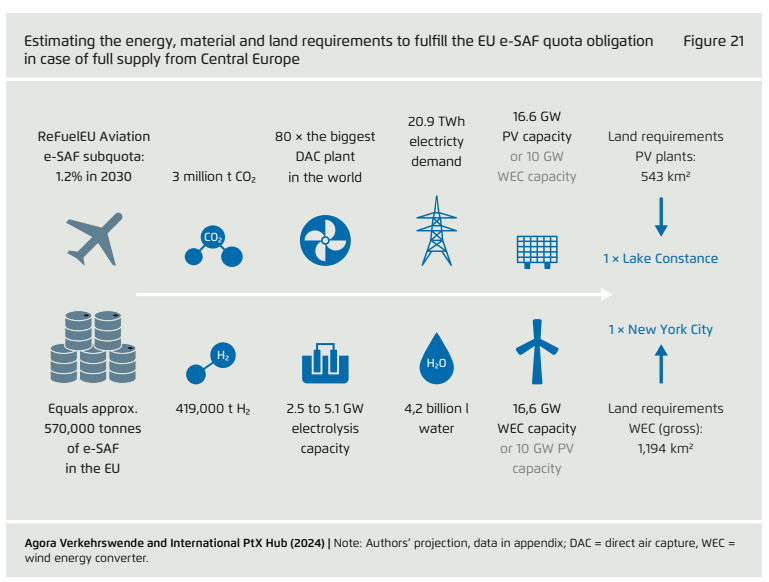

Challenges and requirements for meeting Europe’s e-SAF demand under ReFuelEU aviation regulation

The RFNBO sub-quota under the ReFuelEU aviation regulation will drive significant e-SAF demand in Europe, potentially consuming most global e-SAF production. By 2030, the EU’s obligation will create a demand for about 570,000 tonnes of e-SAF (1.2% of EU jet fuel demand), nearly half of the announced global production capacity. This demand is projected to rise to 950,000 tonnes in 2032 and 2.4 million tonnes by 2035 (2% and 5% of EU jet fuel demand, respectively). To meet these targets, e-SAF from MtJ routes must be included in ASTM standards, necessitating much larger production capacities than planned.

The EU, consuming about 14% of global jet fuel, will need a more ambitious e-SAF ramp-up, requiring substantial supplemental supply-side measures. Meeting future quotas will demand significant construction of synthesis plants, renewable electricity, carbon sources, and electrolysers. Specifically, to meet the 2035 quota, 10.5 to 21.1 gigawatts of electrolysis capacity will be needed, compared to the current global capacity of around 0.7 gigawatts.

To produce sufficient e-SAF, approximately 21 terawatt-hours of renewable electricity will be required. This would necessitate an additional 16.6 gigawatts of PV capacity or 10 gigawatts of wind capacity, with substantial land use considerations. Even if e-fuel production is based in favorable regions outside Europe, immense renewable generation and production capacities will still be necessary.