Ethiopia currently imports billions of dollars’ worth of fossil fertiliser each year to supply its smallholder farmers – to increase crop yields and ensure food security in the country. During the pandemic and the war in Ukraine, global markets increasingly demonstrated the volatility and vulnerability of fertiliser prices to geopolitical shifts. Even in the absence of such crises and wars, the price structure poses a different challenge for farmers in African countries: the price of a tonne of fertiliser in Eastern and Southern Africa can be twice that for a farmer in the US, due to transport and distribution costs. This affects the majority of Ethiopia’s workforce, as up to 90 % are farmers, underlining the crucial role of agriculture in the country.

One strategy to reduce dependence on imported fertiliser is to produce it domestically. Ethiopia’s electricity mix is already 90% renewable, mostly from its hydropower plants, including the 5GW Grand Ethiopian Renaissance Dam. Known as Africa’s water tower, Ethiopia also has access to the water resources needed to produce green hydrogen. This green hydrogen could then be synthesised into green ammonia fertiliser or nitrogenous e-fertiliser. The high premium currently paid for extensive transport networks to land-locked Ethiopia could be saved, and despite the high initial cost of the new technology, sustainably produced e-fertiliser could be a more cost-effective option, in addition to increasing the country’s energy independence.

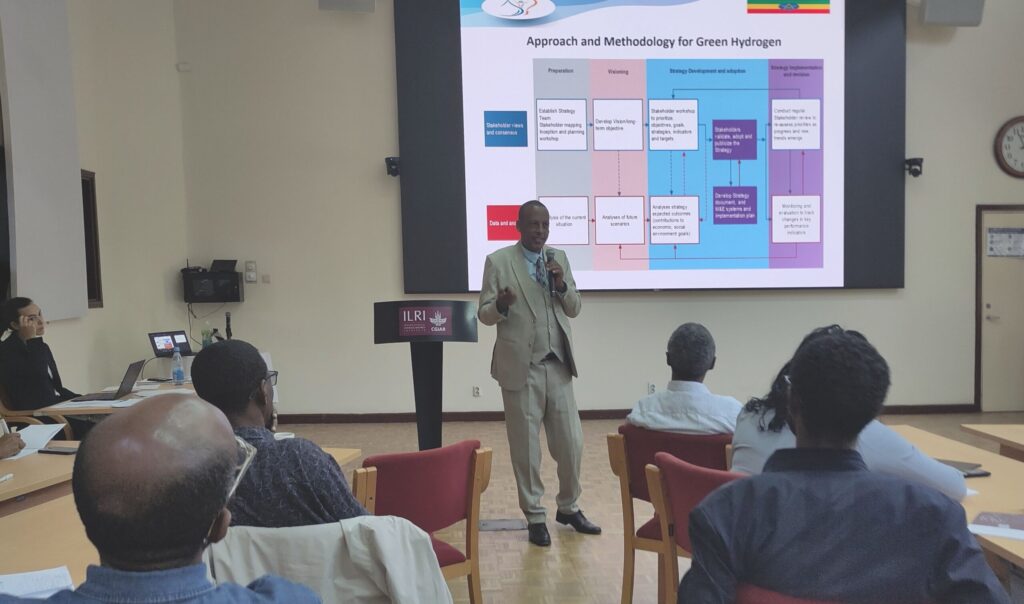

To further explore this opportunity, the Ethiopian-German Energy Cooperation hosted a third training in collaboration with the Ministry of Water and Energy in April 2025, implemented by the PtX Hub. The first workshop in October 2024 identified the two Power-to-X use cases of most interest in Ethiopia: Sustainable Aviation Fuels and e-fertiliser. A second workshop then identified the opportunities and next steps for clean aviation in Ethiopia. In this third and final workshop, participants from the Ministry of Water and Energy, the Ministry of Agriculture, research institutes and start-ups discussed the way forward for domestic e-fertiliser production.

An honest look at the strengths and opportunities, but also weaknesses and threats

The first two days of the training focused on an ongoing discussion of the strengths, weaknesses, opportunities and threats (SWOT) of e-fertiliser production and use in Ethiopia. For example, a wind-solar hybrid site near the border with Djibouti has high potential, as does the already high adoption rate of synthetic fertiliser by farmers, while last mile distribution infrastructure is a challenge, as is the need for investment in research and development.

The bigger picture: sustainable agricultural practices and biofertiliser innovations

To broaden the perspective on sustainable agriculture, the three-day workshop also explored biofertiliser innovations and their role in improving soil fertility. Dr Wondimagegne Mamo Mengistu from the Bio and Emerging Technology Institute presented their zeolite nanofertiliser innovation and how it can be combined with green ammonia fertiliser. Dr Yitbarek Wolde-Hawariat from Addis Ababa University presented waste-to-biofertiliser solutions using black soldier fly larvae, some of which he brought along for a live demonstration. Finally, Dr Asfaw Hailemariam, founder of the Menagesha Biofertiliser Factory, presented his bacteria-in-lignite biofertiliser, which has been produced in a small factory near Addis for more than 12 years. A subsequent tour of the factory gave participants a first-hand look at production, distribution and marketing to smallholder farmers.

This is crucial – as e-fertiliser is not a silver bullet. It must be combined with sustainable agricultural practices, such as precise and timely application, safe handling and climate-resilient crops. E-fertiliser and biofertiliser each play their own role in increasing crop yields, while protecting and nurturing healthy soils.

Learning from international experiences

In addition to the Ethiopian biofertiliser innovations presented, the training also looked to the US, Kenya and Brazil to learn from international experiences in green ammonia production. Vahid Monadjem from Talus AG presented the US company’s innovation of decentralised green ammonia production at farm level. It is currently in production in Kenya, supplying an industrial-scale farmer, the Kenyan Nut Company. Prof Ricardo Ruether, Universidade Federal de Santa Catarina in Brazil, presented the university’s green ammonia production laboratory and highlighted the enabling factors for the use of renewable electricity for fertiliser production: the falling cost of solar PV, the expanding installation capacity worldwide, the potential for agro-photovoltaics itself and for green hydrogen production.

A sound way forward

To provide critical context for a national e-fertiliser strategy, Mr Kaleb Tadesse, Ministry of Water and Energy presented the current status of Ethiopia’s PtX strategy and Mr Shimelis Eshetu, Ministry of Agriculture outlined the country’s current fertiliser import strategy. As a critical first step, a solid baseline assessment of energy and water potentials, existing infrastructure and transport options, and stakeholders needs to be undertaken. The PtX strategy under development provides a viable opportunity to drive the transition to e-fertiliser production. Political support in Ethiopia, the African Union’s Abuja and Nairobi Declarations, and developing carbon markets are just some of the drivers supporting this opportunity to improve energy and food security through e-fertilisers.