Exploring the role of pilot plants in market ramp up

While the hydrogen buzz carries on, it is easy to lose sight of the fact that technology readiness and commercialisation are still in their early stages. Pilot plants are now needed as an intermediate step between laboratory research and full-scale production to facilitate learning and demonstrate viability.

The vital role of pilot plants

As green hydrogen production is closely linked to the availability of renewable energy sources, pilot plants help to optimise the integration of electrolysis processes with variable renewable energy inputs, addressing intermittency and grid integration issues. They also allow the performance and durability of electrolysers and PtX synthesis units to be assessed under real-world conditions. This is critical to understanding the lifetime, maintenance requirements and reliability of PtX components.

It is also essential to optimise and fine-tune the production process before scaling it up to full production. To ensure product quality, operating a pilot plant allows thorough testing and monitoring of product quality under realistic production conditions. This ensures that the final product meets the required standards and specifications.

Pilot plants also allow realistic cost estimates, including the cost of components, consumables and labour. They allow companies to new products for market testing and feedback. This helps to assess consumer preferences and market demand, and provides valuable insights before committing to full-scale production. Finally, transferring technology from research and development teams to production teams ensures a smoother transition from development to large-scale production.

These aspects and more are integral to the concept of the Power-to-Liquid plant in Morocco, initiated by the International PtX Hub and to be realised until 2027.

Why Morocco?

Both in the MENA region and in African regions, Morocco is one of the frontrunners in the energy transition. The country pursues a National Determined Contribution (NDC) that is compatible with the 1.5 degree target of the Paris Agreement. Morocco intends to use this trajectory and leverage its existing experience with renewable energy for the emerging green hydrogen and Power-to-X (PtX) markets.

Morocco’s Ministry of Energy Transition and Sustainable Development views Power-to-Liquid as a long-term business model, driven in particular by European Union legislation, creating market demand for e-kerosene, e-methanol and other PtL products. This opens opportunities to position Morocco as a country for innovation and high quality jobs.

In 2021, Morocco adopted an ambitious Hydrogen Roadmap, which shows its potential to meet between 2% and 4% of global PtX demand by 2030. The roadmap confirms Morocco’s commitment to green industrialisation with PtX and its ambition to become a global player in various PtX products from green ammonia to synthetic fuels. It calls for the first large-scale industrial projects to produce synthetic fuels for export from 2030 and for domestic use from 2040 on. The next ten years are therefore the critical window for testing the technologies and developing skills through pilot projects.

Piloting for technology readiness and capacity building

Bringing Power-to-Liquid technology to market maturity and building capacities: these are the main objectives of the planned Power-to-Liquid pilot plant in Morocco. Specifically, the technology readiness level (TRL) should be increased from levels around 7 to 9 (7= prototype system demonstration in an operational environment to 9=actual system proven in operational environment).

There is already strong investor interest in large-scale green ammonia projects in Morocco, so this pilot plant will additionally support the e-fuels production route in Morocco. The production process will be adapted and optimised to local conditions characterised by arid climate and coastal weather. Finally, it will build confidence and knowledge of the new technology.

In light of the shutdown of the last refineries in Morocco in 2015, it is of national interest to re-strengthen the Power-to-Liquid process know-how and to increase fuel production independence again. The MENA region currently has a shortage of skilled workers in the energy sector, in contrast to the 13,500 additional jobs to be created by PtX by 2030.

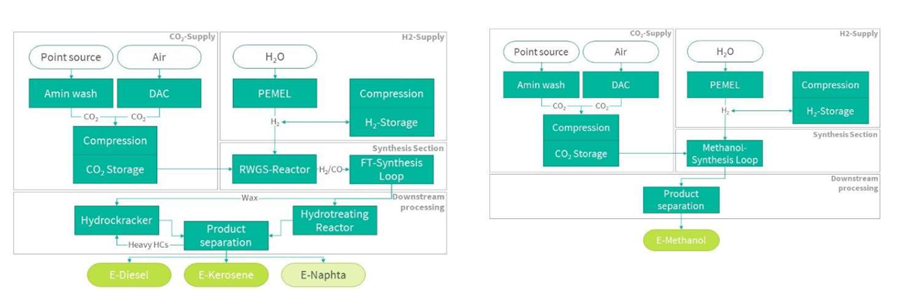

The pilot plant will provide training sessions and test labs for various professionals working in the Power-to-Liquid value chain, including construction, process, operations, and maintenance. The plant will produce e-kerosene (Fischer-Tropsch based Sustainable Aviation Fuel) or e-methanol via Polymer Electrolyte Membrane (PEM) electrolysis and CO2 input.

Moroccan R&D platform to ensure continuity

L’Institut de Recherche en Énergie Solaire et Énergies Nouvelles (IRESEN), a Moroccan R&D agency affiliated with the Moroccan Ministry of Energy Transition and Sustainable Development (MTEDD), has launched the Green H2 Applications Platform (GH2A) to provide an R&D and training platform open to both industry players and international academic teams. The first pilot plant to be hosted by GH2A will be a Power-to-Ammonia system with a total capacity of 4 MW and an annual production of around 1,400 tonnes. The Power-to-Liquid pilot plant will also be integrated into the platform, to ensure continuity and tap into existing structures for capacity building.