Add-on Module

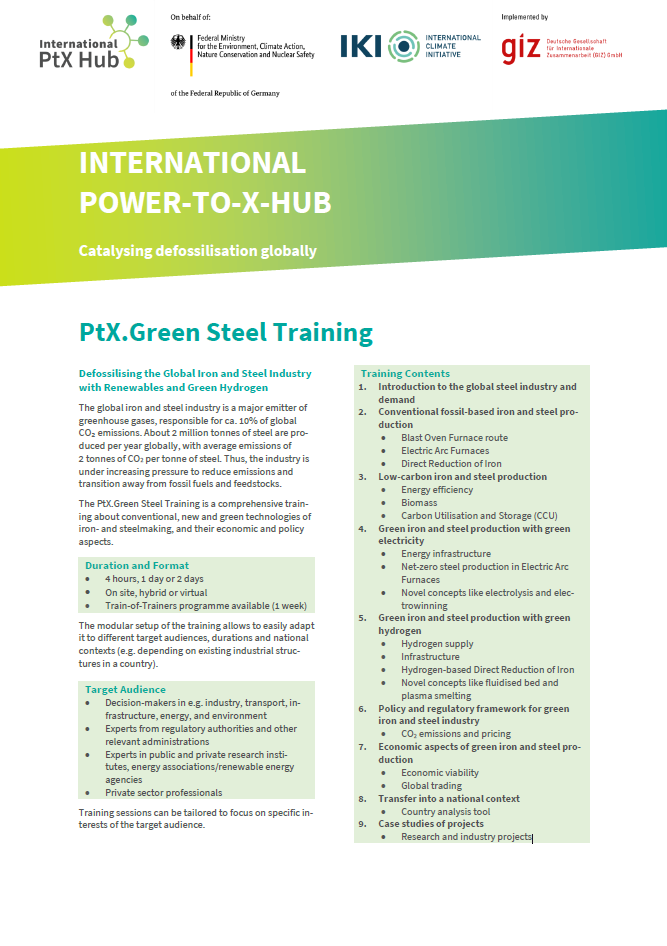

Green Steel

Training goal / learning outcome

The global iron and steel industry is a major emitter of greenhouse gases, responsible for around 10% of global CO₂ emissions. About 2 million tonnes of steel are produced per year globally, with average emissions of 2 tonnes of CO₂ per tonne of steel. Thus, the industry is under increasing pressure to reduce emissions and transition away from fossil fuels and feedstocks.

The PtX.Green Steel Training is a comprehensive training about conventional, new and green technologies of

iron- and steelmaking, and their economic and policy aspects.

Target audience

- Decision-makers in industry, transport, infrastructure, energy and environment

- Experts from regulatory authorities and other relevant administrations

- Experts in public and private research institutes, energy associations and renewable energy agencies

- Private sector professionals

Format

Online, onsite, or hybrid

Modules / content

- Introduction to the global steel industry and demand

- Conventional fossil-based iron and steel production

• Blast Oven Furnace route

• Electric Arc Furnaces

• Direct Reduction of Iron - Low-carbon iron and steel production

• Energy efficiency

• Biomass

• Carbon Utilisation and Storage (CCU) - Green iron and steel production with green

electricity

• Energy infrastructure

• Net-zero steel production in Electric Arc

Furnaces

• Novel concepts like electrolysis and electrowinning - Green iron and steel production with green

hydrogen

• Hydrogen supply

• Infrastructure

• Hydrogen-based Direct Reduction of Iron

• Novel concepts like fluidised bed and

plasma smelting - Policy and regulatory framework for green

iron and steel industry

• CO2 emissions and pricing - Economic aspects of green iron and steel production

• Economic viability

• Global trading - Transfer into a national context

• Country analysis tool - Case studies of projects

• Research and industry projects

Duration

4 hours, 1 day or 2 days

Status

Running

At a glance:

Interested? Contact:

Thomas Elmar Schuppe

My main projects are the development of Renewable PtX trainings and to organise comprehensive Train-of-Trainer courses. I am convinced that Renewable PtX ought to be the missing building block to effectively decarbonise and defossilise respectively, entire economies at scale.

Focus

I focus on finding the appropriate formats and topics to improve our adult learning formats on Renewable PtX continuously and scaling up the number of our international multiplicators in our partner countries.

Mission

Aquiring specific knowledge is key for a broad and global transition in the partner countries of the international coorperation. The PtX.Academy provides the suitable and up-to-date formats for effective Human-Capacity-Development with our partners.