Collaboration is key – this is one of the key takeaways from our first ACHEMA study tour two years ago. So this year’s study tour again focused on bringing together policy makers and researchers from Argentina, Kenya, Morocco and South Africa with German research initiatives and companies to learn from each other.

Introducing German key research initiatives

Dechema, who organised the study tour as part of the PtX Hub, welcomed the delegation to kick off the week. Dr. Andreas Förster, Executive Director of DECHEMA gave a warm welcome to get to know the German chemical industry ecosystem. Thomas Hild introduced the German flagship project H2Giga, which aims to make serial mass production of electrolysers possible.

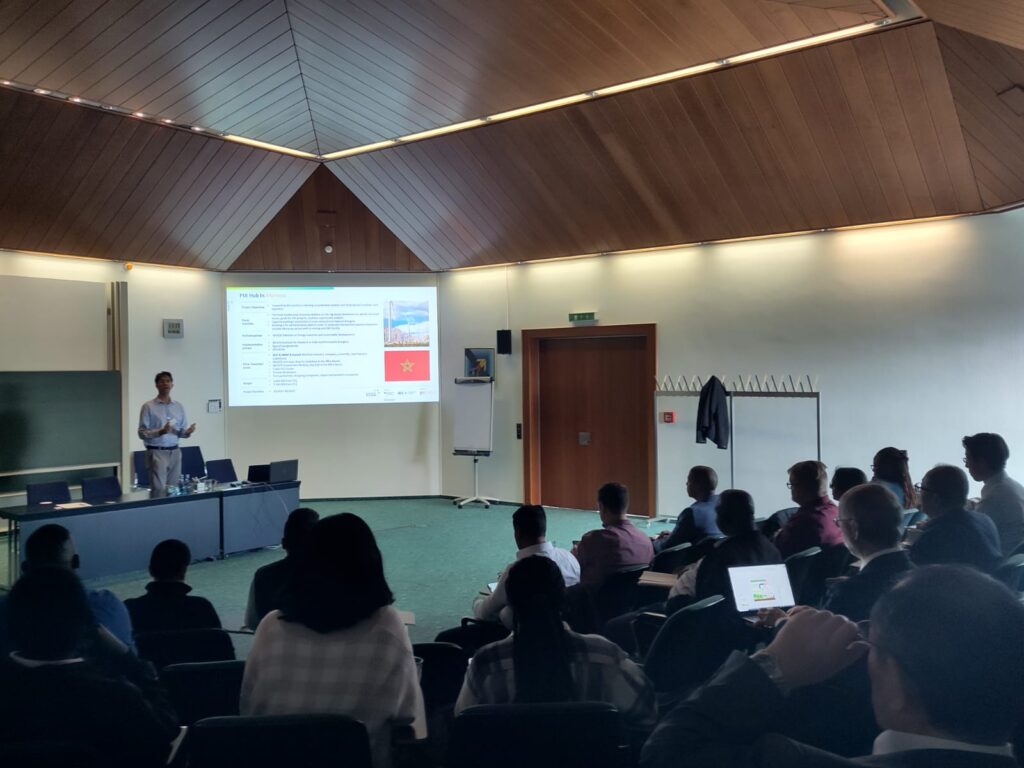

Matthias Rilling presenting the PtX Hub’s activities in Morocco at the welcome reception at Dechema House.

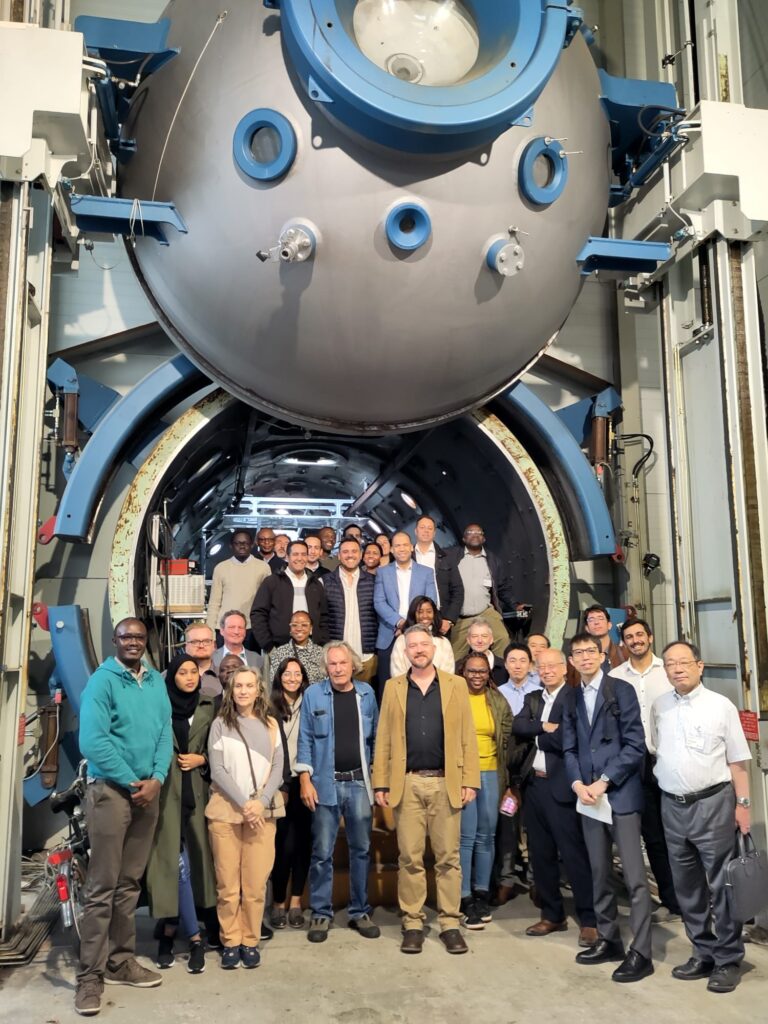

Group of delegates networking.

Integrating processes at industrial park Höchst and constructing the world’s largest Power-to-Liquid plant

After a welcome reception and a networking lunch, the delegation travelled by local train to the industrial park Höchst in Frankfurt. The park is home to 120 companies and 22.000 jobs. The bus tour of the park focused on the production and use of renewable hydrogen, including hydrogen infrastructure and refuelling stations. A highlight was the fleet of 27 hydrogen trains already in operation.

Start up Ineratec presented its Power-to-Liquid plant, which is currently under construction and will be the largest in the world. Up to 3,500 tonnes or 4.6 million litres of e-fuels will be produced annually from up to 10,000 tonnes of biogenic CO2 and renewable electricity.

Safe hydrogen handling and Biomass-to-Liquid at Karlsruhe Institute for Technology (KIT)

The second day started with a trip to the Karlsruhe Institute of Technology (KIT), where their latest research on safe hydrogen handling and Biomass-to-Liquid technology was presented. The hydrogen test centre HYKA of the Institute for Thermal Energy Technology and Safety (KIT-ITES) routinely tests the safety of handling hydrogen. The Bioliq pilot plant is testing the use of various forms of biomass to produce liquid fuels. The pilot research initiative now concludes having proven the technology.

The delegation at the hydrogen test center HYKA of the Institute for Thermal Energy Technology and Safety (KIT-ITES).

The Bioliq Biomass-to-Liquid pilot plant at KIT.

Thyssenkrupp’s Carbon2Chem: using blast furnace gas from steel mills to produce methanol

After the welcome and introduction at Thyssenkrupp’s headquarters in Essen on Friday, Thyssenkrupp introduced their companies Thyssenkrupp Uhde, Nucera and Steel. Cristopher Frank presented their Power-to-X technologies for the production of green basic chemicals such as ammonia and methanol as well as synthetic fuels. Dr Nina Kolbe presented the use of hydrogen in direct reduction steelmaking and the role of the Carbon2Chem pilot plant in the transformation pathway of Thyssenkrupp steel. Thyssenkrupp plans to build the largest direct reduction steel plant in Europe. Finally, Clarissa Steinweider presented the electrolysis technology of Thyssenkrupp Nucera.

Carbon2Chem is piloting a way to make steel greener. The plant produces methanol using blast furnace gas from the nearby steelworks. Phase three of the project is due to start soon.

The pipes transferring blast furnace gas from the closeby steel mill to the pilot plant.

The Carbon2Chem pilot plant.

Bringing an international perspective to ACHEMA 2024

At the ACHEMA, the world’s leading trade show for the process industries in Frankfurt, the delegations had the opportunity to meet manufacturers and service providers from over 50 countries, showcasing their products for chemical, pharmaceutical and biotech research and manufacturing as well as energy and environmental services.

Two sessions by the Dechema, the PtX Hub and the delegations brought an international perspective to the ACHEMA. In a morning panel by Dechema, experts from Argentina, Morocco and South Africa presented the opportunities and challenges of Power-to-X in their countries.

Panelists at Dechema session.

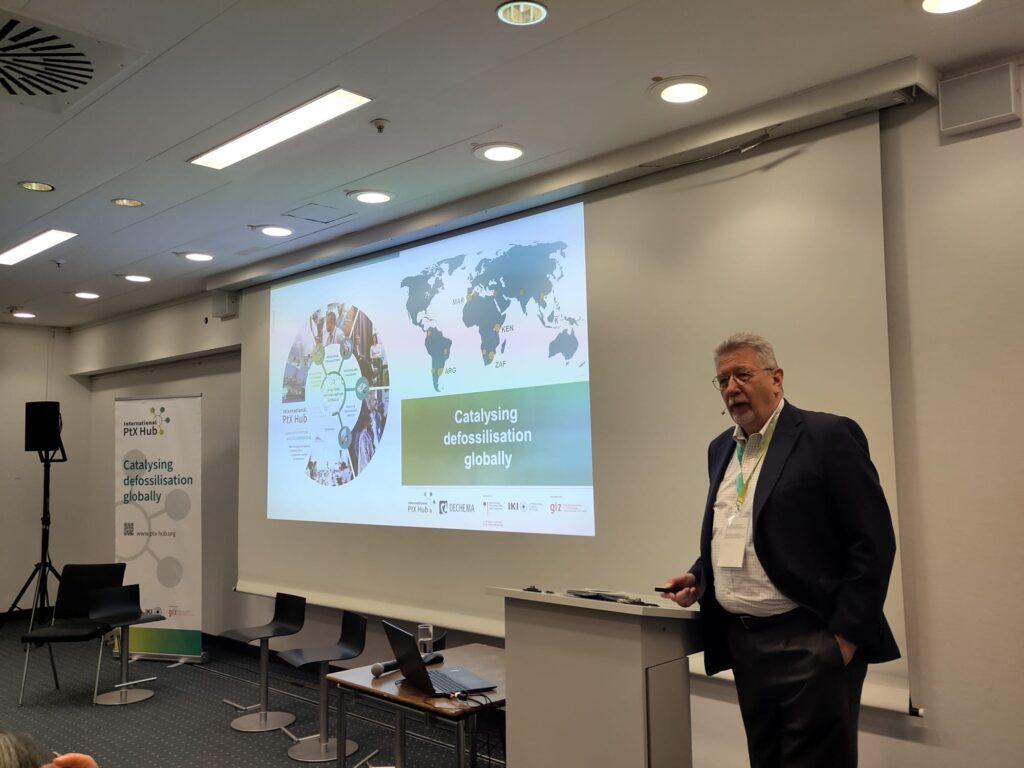

Heino von Meyer, PtX Hub moderating the session.

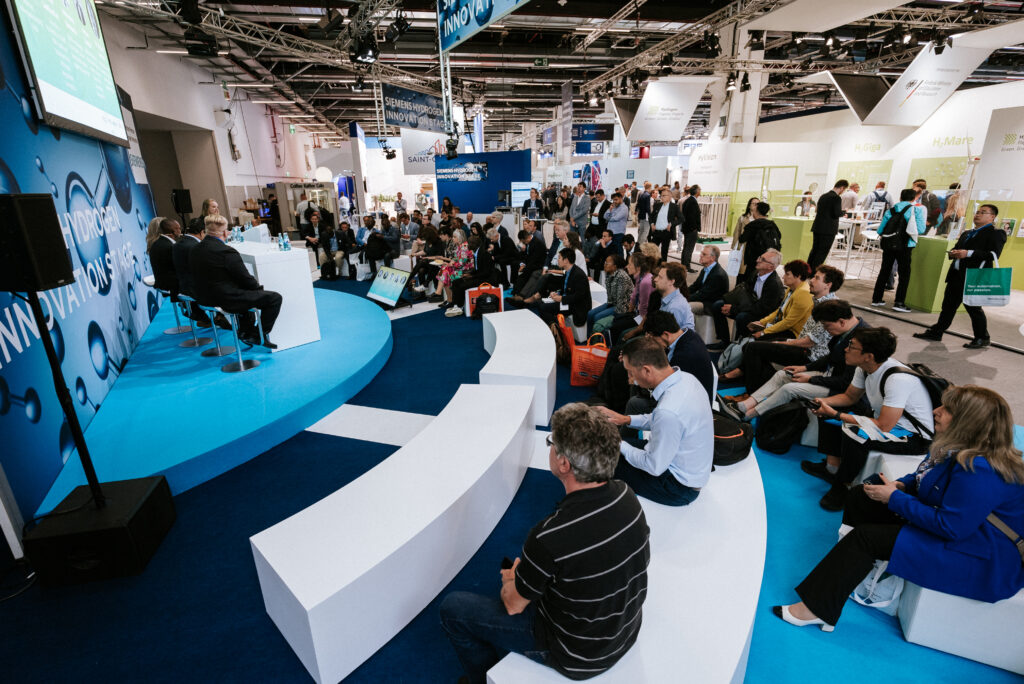

The Siemens Hydrogen Innovation Stage hosted the PtX Hub’s afternoon session on concrete use cases for Power-to-X in Argentina, Kenya, Morocco and South Africa.

Griselda Lambertini, Directora Académica, CEARE – UBA Centro de Estudios de la Actividad Regulatoria Energética, shared the Argentinian National Hydrogen Strategy, highlighting green hydrogen for local and export markets, leveraging Argentina’s natural gas network, and addressing technological and market challenges. Mohamed Bousseta, CEO Green Energy Park, UM6P – Mohammed VI Polytechnic University, emphasised Morocco’s large investments in green hydrogen and ammonia production, tackling transport logistics of these products to Europe, and the need for skilled labor to achieve carbon neutrality by 2040. Antony Langat, Assistant Manager, Manufacturing and Industry, Kenya Electricity Generating Company PLC, discussed Kenya’s renewable energy strategy focusing on geothermal, hydro, and hydrogen, integrating green hydrogen into agriculture, and enhancing regulatory frameworks to attract investments. Dr Rigardt Coetzee, Senior Researcher, Council for Scientific and Industrial Research (CSIR), focused on green steel production in South Africa, addressing financial challenges, and developing green corridors in the region for export.

PtX Hub panel on the Siemens Hydrogen Innovation Stage. © Daniel Mayorov, ExpoMedia

Audience during the panel. © Daniel Mayorov, ExpoMedia

The week-long trip demonstrated the momentum of international cooperation and technology research and adoption for green hydrogen and Power-to-X to enable the transition to sustainable chemical industries globally.